How we control product quality?

Our company establish a quality control process in production strictly and QC department including 4 people in charge of checking quality in every manufacturing production before delivering products to our customers.

Product quality is one of the main factors that B2B buyers highly pay attention to. Understanding customers’ needs, we focus on choosing high-quality input materials and controlling the quality of every process. Here is our process to apply in our system, factory including 4 main activities: input materials selection, mass production, packing, and worker training.

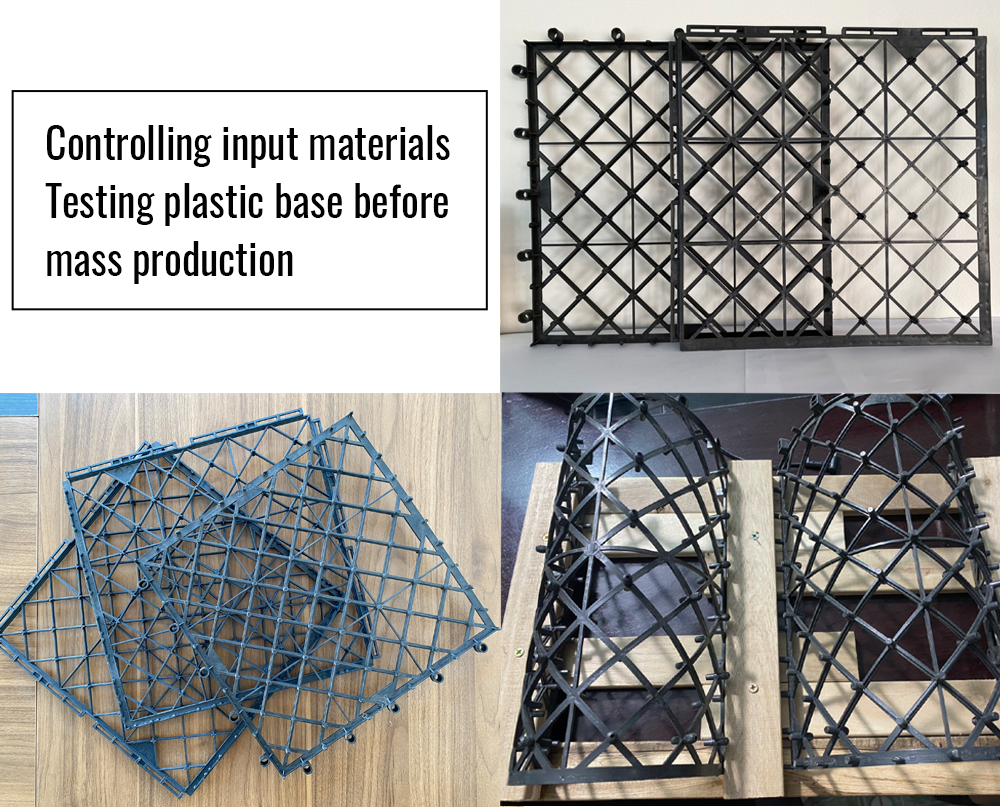

Input Materials

The input materials are Acacia wood and plastic base that is controlled by co-operating with selected suppliers. We choose Acacia being our main material because of its stable capability, high quality, durable at a competitive price. Before mass production, we must test the toughness of the plastic base.

Mass Production

Our QC department includes 4 people in charge of checking quality in every manufacturing production before delivering products to our customers to ensure customers receive products free from defects and meet their needs.

Packaging

The QC department checks product quality before packaging. Regarding customer requirements, we could customize the number of tiles in a box, support graphic design, or logo.

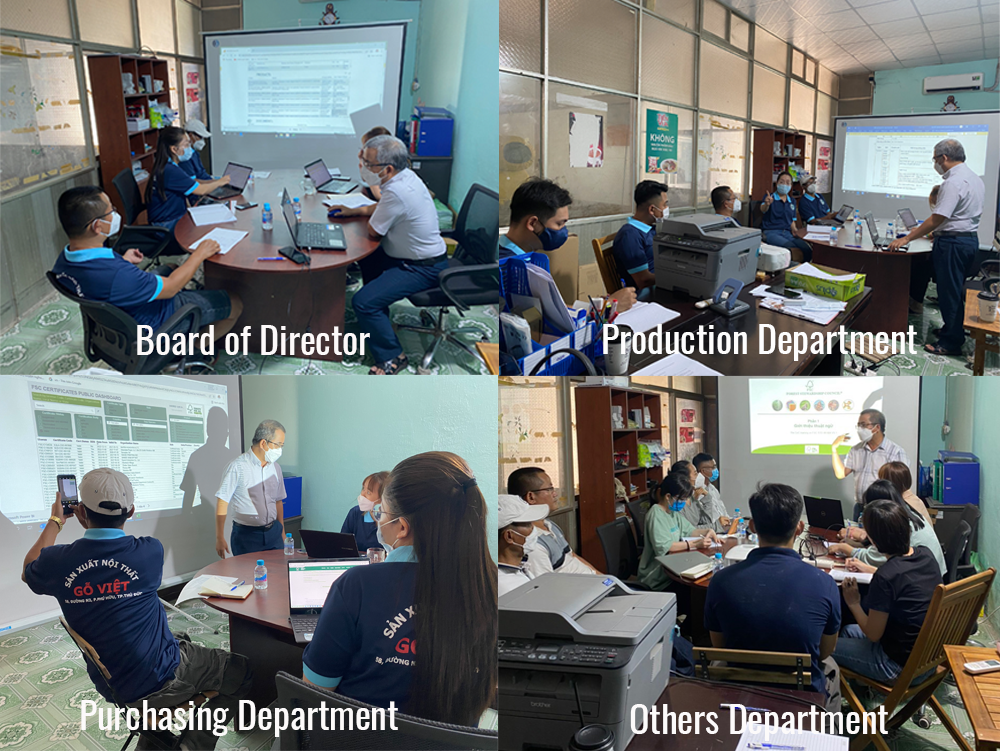

Employee training program manually

In correspondence with the control quality process, we also have a manual program for training employees, managers, and workers.

- Can wood deck tiles be installed in bathroom? (28/05/2023 19:00:03)

- Deck Tiles Production Process (04/06/2022 13:21:38)

- Ideas To Decorate Your Balcony (03/06/2022 13:07:03)

- Advantages of outdoor deck tiles (02/06/2022 09:46:27)

- Our Wood Deck Tiles Is Coming To Germany (01/06/2022 15:19:55)

- Viet Wood FSC Certification (26/05/2022 12:28:02)

- Installation tips of wood deck tiles (18/02/2020 14:19:38)

- Installation tips of wood deck tiles (03/08/2018 16:27:11)

- On what surfaces can you install wood deck tiles? (03/08/2018 14:11:44)

- New trend flooring with wood deck tiles (30/07/2018 11:44:14)

- Hot trend hardwood flooring with Acacia wood deck tiles in summer (20/07/2018 16:42:21)

- Wood deck tiles - Good change - New idea (18/07/2018 12:11:53)

- New trend - Wood deck tiles (17/07/2018 16:59:12)

- Why you choose charcoal? (14/07/2018 10:44:20)

- Why finger joint board uses? (13/07/2018 16:17:19)

- Wood Deck Tiles for relatively easy to install and friendly user (12/07/2018 17:03:22)

- Adjustable Charcoal From Sawdust from Vietnam 2018 (11/07/2018 15:24:19)

- What is Rubberwood? (10/07/2018 17:12:30)

- The best charcoal for grill (09/07/2018 11:04:10)

- A part in the production process of Finger Joint Board (Part 1) (07/07/2018 09:39:06)

- A part in the production process of Finger Joint Board (Part 2) (07/07/2018 09:32:42)

- 300 x 300 x 19 mm Acacia Wood Deck Tiles (06/07/2018 16:18:05)

- Eucalyptus Core Veneer (06/07/2018 10:42:20)

- Standards customized of Finger Joint Board to come Korea (05/07/2018 16:49:21)

- Standards customized of Finger Joint Board to come Korea (05/07/2018 16:49:10)

- Wood deck tiles - The newest trend of exterior setting in summer (05/07/2018 14:17:38)

- Sawdust Charcoal - the best choice for BBQ (05/07/2018 13:57:58)